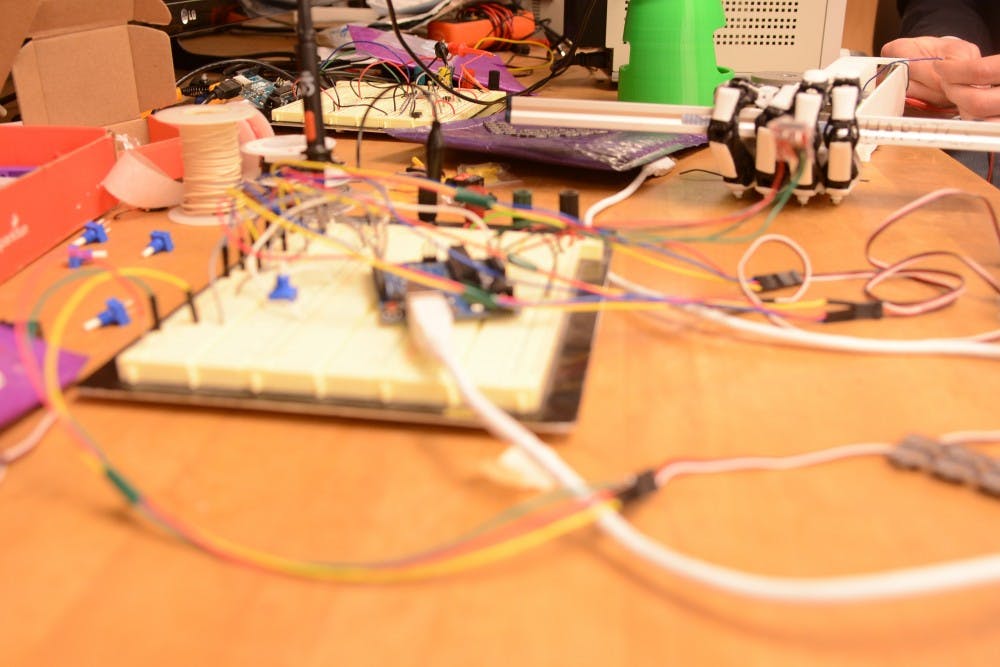

The circuit board detects pressure on sensor chips that are used to convey the sense of touch to a user.

Credit: Esther JouFive Engineering seniors are changing the life of an 8-year-old boy while revolutionizing the field of 3-D printed prosthetics for their senior project.

Matthew, called “Matty” by his friends and family, is a dolphin-loving third grader who lost his left arm from the elbow down to cancer at a young age.

“He is strong and determined and does everything he puts his mind to,” said Maura Walshok, Matty’s occupational therapist, in an email. “He is also one of the sweetest and most compassionate kids you will ever meet.”

Team members Matthew Lisle, Adrian Lievano, Aadithya Prakash, Steven Xing and Freddy Hernandez combined their skills of mechanical and electrical engineering to 3-D print Matty a new prosthetic arm, which they call BionUX, which stands for Bionic Upper Extremity.

Although Matty is a huge sports fanatic and even pitches for his baseball team, the engineers hope to help Matty with a few tasks that his disability has prevented him from doing, like riding a bike or holding down the paper on which he is writing.

“It’s the things that you never realized were so important,” Lisle said. “But when you previously didn’t have that ability to do something before and now you do, that’s a big deal.”

The BionUX arm is pioneering new techniques in the field of prosthetics. 3-Dhyphen printing the arm allows for a customized fit and a lower price point. The team has also integrated complex electronics to allow for sensory feedback, which could provide Matty with a sense of touch.

The arm works by attaching sensors in the prosthetic fingers to the skin on the upper arm of the wearer. The goal is that when Matty touches something, he will be able to feel a similar sensory experience in the brain as if his hand were actually touching it.

“Other 3-Dhyphen printed prosthetics are passive with no motors or electronics,” Lievano said. “This is a huge step up from preliminary prosthetics and a tangent from the most expensive ones.”

The team met Matty and began working on their project with the help of several experts in the field, including prosthetist Alberto Esquenazi of Advanced Arm Dynamics, a company specializing in fitting amputees with technologically advanced upper arm prostheses.

“The goal is to try and allow individuals to do more things on their own and be more independent,” Esquenazi said. “We also try to work with them so that they don’t end up injuring their remaining arm.”

Walsh, who has worked with Matty since he was an infant, hopes that the arm will help him gain confidence and even more acceptance among his peers.

“Even since we began talking about him getting the arm, so many of his peers are interested and have great questions about it,” Walsh said in an email.

“This makes him cooler and half robotic,” Lievano added. “He loves it.”

This soon-to-graduate team is not stopping at helping Matty. Lisle explained that they have applied to several competitions, hoping to receive grant money that would allow them to continue their work in advancing this new field of prostheses.

“There are a lot of hobbyists involved and not as many qualified experts [in 3-Dhyphen printing],” Lievano said. “There is potential in recruiting more design engineers to orchestrate a larger effort.”

A previous version of this article referred to Aadithya Prakash as Prathik Prakash. The DP regrets the error.

The Daily Pennsylvanian is an independent, student-run newspaper. Please consider making a donation to support the coverage that shapes the University. Your generosity ensures a future of strong journalism at Penn.

DonatePlease note All comments are eligible for publication in The Daily Pennsylvanian.